Keretapi Tanah Melayu Bhd (KTMB) faces losses running into millions of ringgit if some of its railway track parts are not changed soon.

Worse still, the lives of passengers could be at risk as further deterioration of the parts could cause derailment, among other things.

A probe by The Malay Mail the last two months revealed that the railway fasteners, particularly the Fastclip designed by UK-based company Pandrol, showed signs of deterioration.

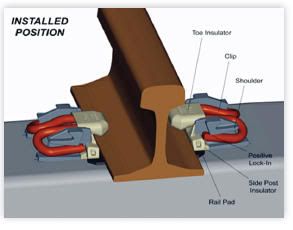

Railway fasteners are heavy-duty clips used to fasten rails to the base plate (or ‘sleeper’) to secure the tracks in place and keep them parallel.

Each set of the Pandrol Fastclip comprises four components: a toe insulator, a clip, a shoulder, and a side post insulator. The fastener is installed on top of a rail pad made out of rubber (see graphic).

In Malaysia, the Fastclip was first installed on the Tanjung Pelepas Port (PTP) line in Johor in 2002. The project was a turnkey project worth RM470 million.

According to Pandrol, the Fastclip is supposed to have a lifespan of 15 years. However, after only seven years on the PTP line, some of the components have deteriorated so much that it has been deemed unsafe for use.

A source familiar with KTMB matters said the ‘degrading’ part of the fastener was the toe insulator, which is made of plastic.

“The toe insulator facilitates loading of the rail clip and resists movement of the clip or the rail during use. A slight crack in the toe insulator may still be okay but if it is damaged extensively, it may cause track-derailment.

“The toe insulators also work to send electricity signals from the train tracks to the stations. If the insulator breaks, the signals sent would be distorted. We can’t afford to have distorted signals in our railroad communication as everything is supposed to be automated and scheduled.”

When The Malay Mail visited the PTP line in Gelang Patah recently, we discovered many of the toe insulators were in poor condition.

We observed the toe insulators were made out of plastic, though not the ordinary type.

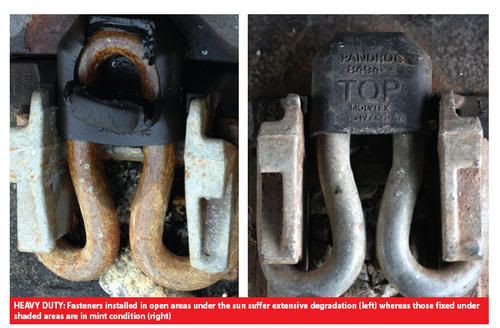

We also observed that the degraded toe insulators were only those that had been installed in open areas and exposed to the sun. Those installed in the shade, such as under bridges and elevated highways, were still in mint condition (see pic above).

A KTMB staff from its Permanent Way Division, who declined to be named, said: “The material used to make the plastic is unique in terms of its chemical composition. The material is supposed to be solid enough to withstand normal wear and tear for 15 years, but we learned the hard way that the Malaysian weather had proven to be too much for it.”

The second railway line in the country to be installed with the Fastclip was the Ipoh-Rawang Electrification Double-Tracking System in 2004.

Our recent checks there revealed that some of the toe insulators have begun to show signs of degrading as well, despite being installed for only four years.

It was learnt that there is another popular brand of railway fasteners installed along KTMB lines, the German-made Vossloh W14, which has proven to be less problematic than the Pandrol Fastclip.

Asked why the Fastclip was used rather than standardising the usage with Vossloh throughout the country, the staff claimed there were "political interests" in the decision-making process.

“Different contractors want to push different brands based on who their suppliers are. And there are different political figures behind these contractors.

“At the time of installation, the Pandrol Fastclip was one of the most modern technologies, so we agreed to use them for our tracks.

"We didn’t know the material would be unsuitable for our weather. The Fastclip installed in cooler climate countries do not have this problem.

“For KTMB, as long as the parts fit our technical requirements, we are okay with any brand,” said the staff, without elaborating further.

The staff said to have a standard set of railway fasteners throughout the country would be fantastic, but that decision was not up to KTMB, which comes under the purview of the Transport Ministry.

PANDROL TO WORK ON NEW MATERIAL.

After being informed of the problem with the Pandrol Fastclip toe insulators, the company sent a technical expert from Britain to Tanjung Pelepas Port in Gelang Patah, Johor, last month to carry out an inspection of the rail tracks.

A KTMB staff with the Permanent Way Division told The Malay Mail that during the inspection, the expert said the problem with the toe insulators resulted from incorrect installation.

“That is, of course, untrue. We are not stupid.... we know how to install railway fasteners correctly. We’ve been doing it for decades!" he said.

“After considering our conclusion that the problem was in the material used to make the toe insulators, the expert agreed to return to Britain and come up with a material of different chemical composition, one that could withstand the heat of the Malaysian sun.”

The staff said the expert also agreed to allow KTMB to test the new material here before making the decision to replace all degraded toe insulators with the new ones.

The staff claimed the two parties also agreed that Pandrol would bear the full cost of the replacement.

“If Pandrol can’t fix this problem, then we won’t be taking anymore of their devices for our future projects.”

The Malay Mail sent several emails to Pandrol in Britain to seek clarification on the matter. However, our efforts to date have proved futile.

VANDALISM WOES FOR PORT LINE

Deteriorating components are not the only problem Keretapi Tanah Melayu Bhd (KTMB) faces on its Tanjung Pelepas Port (PTP) railway line.

A recent visit by The Malay Mail revealed that the line faces several other problems, the most common being vandalism.

A spokesman for KTMB in Gelang Patah said this was an age-old issue, on which they had pretty much given up trying to combat.

The 35km track is located within industrial surroundings on rural roads. We observed that the line is not fenced off and the sides of the track are wide enough for motorcycles and even four-wheelers to pass through.

“The vandals will steal whatever they can get their hands on – steel, metal and fibre, railway fasteners, circuit cables... even one of our point machines was carried away.

"Many of our lamp signals are also gone. The only thing they can't carry away is the concrete lamp post,” said the spokesman.

He said for railway fasteners, the UK Pandrol Fastclip had been proven easier to steal than the German-made Vossloh W14.

“The Fastclip is installed in such a way that one can just knock the fastener out of its socket with a sledgehammer.

“But for Vossloh, the fastener is screwed into the ground; therefore it takes more effort and a longer time to dislodge.” (see pic above)

At one point during our visit, we saw KTMB workers having to change a track course manually. The designated point machine that was supposed to change the track direction automatically "disappeared" months ago, we

were told.

To change the course of the track for trains to pass through, KTMB staff had to ride the line in a small trolley to the designated spot where two tracks are joined, unlock the clip locks with a key and turn the crank manually to change the track direction from one line to another.

After a train had passed, the staff would then have to change the track back to its original course. The entire process takes 15 to 20 minutes each time and is carried out by at least three people.

If previously the PTP staff were able to know of an oncoming train from another station via communication signals sent from the tracks, they now rely on telephones and walkie-talkies to communicate with one another on train movements.

As if that was not enough unnecessary work, the staff would also ride the lines daily to check for rocks and pebbles that vandals would neatly arrange on the tracks.